The quality of our cylinders

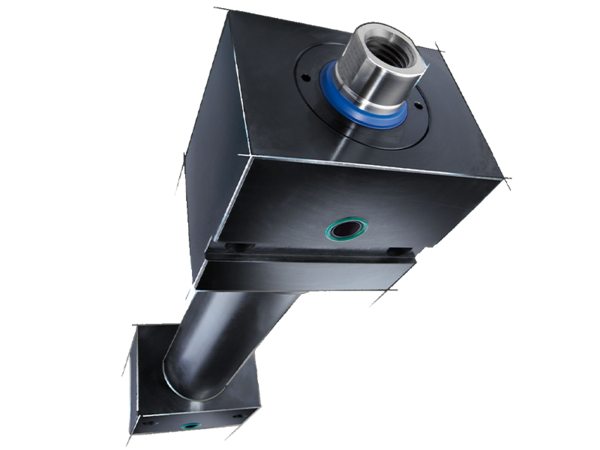

AHP Merkle focuses on innovation by identifying core priorities and optimizing solutions for customers. We emphasize efficiency and cost-effectiveness while pioneering new approaches. Our systematically structured product range ensures logical consistency and high service standards. A key feature is our modular design system, allowing flexible cylinder configurations and facilitating the creation of customized products.

Declarations of conformity

AHP Merkle focuses on innovation by identifying core priorities and optimizing solutions for customers. We emphasize efficiency and cost-effectiveness while pioneering new approaches. Our systematically structured product range ensures logical consistency and high service standards. A key feature is our modular design system, allowing flexible cylinder configurations and facilitating the creation of customized products.

Certificates

AHP Merkle focuses on innovation by identifying core priorities and optimizing solutions for customers. We emphasize efficiency and cost-effectiveness while pioneering new approaches. Our systematically structured product range ensures logical consistency and high service standards. A key feature is our modular design system, allowing flexible cylinder configurations and facilitating the creation of customized products.