The gate point diameter of tunnel gate inserts “Standard” is already completely constructed. Due to the special manufacturing method all gate point diameters from 0,6 to 2,8 are clearly reproducible.

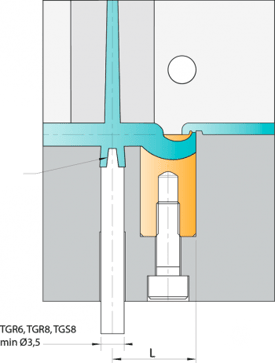

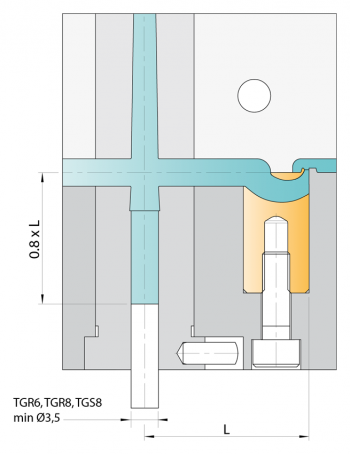

Tunnel gate inserts version S2 can be installed directly. You drill the hole – we supply the proper tunnel gate insert.

| TGR 6 | TGR / TGS 8 | TGR / TGS 10 | TGR / TGS 12 | TGR / TGS 14 | |

|---|---|---|---|---|---|

| Gate size | 0.6 | 0.6 / 0.8 | 0.8 / 1.2 / 1.6 | 1.2 / 1.6 / 2.0 | 1.6 / 2.0 / 2.4 / 2.8 |

| Channel Ø (mm) | 2.5 | 3 | 4 | 5 | 6 |

| Low viscosity (NV)* | 3 | 5 | 30 | 50 | 200 |

| Medium viscosity (MV)* | 2 | 4 | 20 | 35 | 120 |

| High viscosity (HV)* | 1 | 3 | 12 | 25 | 75 |

* Maximum shot weights (g) | NV: low viscosity | MV: medium viscosity | HV: high viscosity

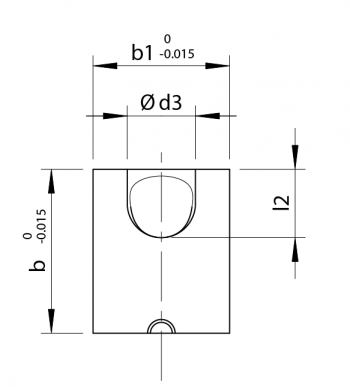

| Type | b | b1 | d1 | d2 | d3 | h | h1 | h2 | l1 | l2 | M | Version |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TGS8 | 8 | 6 | 0.6 / 0.8 | 1.9 / 2.1 | 3 | 22.0 | 0.6 | 1.1 | 13 | 3.25 | 4 | S2 |

| TGS10 | 10 | 8 | 0.8 / 1.2 / 1.6 | 2.2 / 2.6 / 3.0 | 4 | 22.0 | 0.8 | 1.2 | 12 | 4 | 5 | S2 |

| TGS12 | 12 | 10 | 1.2 / 1.6 / 2.0 | 2.6 / 3.0 / 3.4 | 5 | 22.0 | 0.8 | 1.4 | 11 | 5 | 5 | S2 |

| TGS14 | 14 | 12 | 1.6 / 2.0 / 2.4 / 2.8 | 3.0 / 3.4 / 3.8 / 4.2 | 6 | 22.0 | 0.8 | 1.6 | 10 | 6 | 6 | S2 |

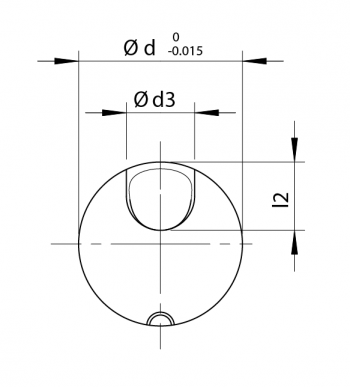

| Type | d | d1 | d2 | d3 | h | h1 | h2 | l1 | l2 | M | Version |

|---|---|---|---|---|---|---|---|---|---|---|---|

| TGR6 | 6 | 0.6 | 1.9 | 2.5 | 17.0 | 0.6 | 0.8 | 10 | 2.5 | 4 | S2 |

| TGR8 | 8 | 0.6 / 0.8 | 1.9 / 2.1 | 3 | 22.0 | 0.6 | 1.1 | 13 | 3.25 | 4 | S2 |

| TGR10 | 10 | 0.8 / 1.2 / 1.6 | 2.2 / 2.6 / 3.0 | 4 | 22.0 | 0.8 | 1.2 | 15 | 4 | 5 | S2 |

| TGR12 | 12 | 1.2 / 1.6 / 2.0 | 2.6 / 3.0 / 3.4 | 5 | 22.0 | 0.8 | 1.4 | 11 | 5 | 5 | S2 |

| TGR14 | 14 | 1.6 / 2.0 / 2.4 / 2.8 | 3.0 / 3.4 / 3.8 / 4.2 | 6 | 22.0 | 0.8 | 1.6 | 10 | 6 | 6 | S2 |

| Type | TPE, TPU etc. | PE, PP, PET etc. | PC/ABS, PA, POM, HI-PC etc. | PA+GF, PC, SAN, PMMA etc. |

|---|---|---|---|---|

| TGR 6 | 9–12 | 12–18 | 15–22 | 18–25 |

| TGR/TGS 8 | 11–14 | 15–22 | 19–27 | 23–30 |

| TGR/TGS 10 | 15–18 | 19–27 | 24–33 | 28–36 |

| TGR/TGS 12 | 18–22 | 22–30 | 27–36 | 32–40 |

| TGR/TGS 14 | 20–25 | 25–33 | 30–37 | 35–43 |

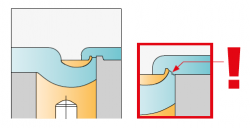

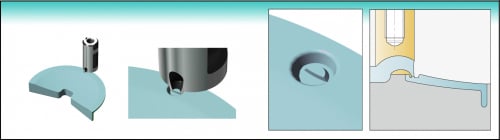

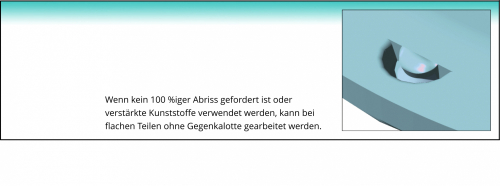

For optimum degating (especially of flat parts) we recommend the use of a companion vestige supplementing the vestige with cutting edge. This configuration will ensure that the part is separated from the runner flush with the parting line. Users will find this particularly advantageous in cases where materials are susceptible to stringing

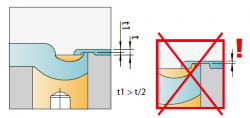

If the molded part is very thin, the vestige must be ground down. (t1>t/2)

CYTECUK specializes in high-precision hydraulic cylinders, clamping systems, milling heads, and motor spindles for various industrial applications, including tool & mold making, the automotive industry, and aerospace.

Hydraulic cylinders are essential components in fluid technology, enabling precise linear movements and high forces

Core pull and locking cylinders are specialized hydraulic cylinders used in injection moulding machines for the precise movement and securing of moulds

Our products, such as air valves, sliders, and gas injectors, enhance the performance and reliability of your injection moulds

CYTEC specializes in hydraulic cylinder technology, offering advanced cylinder and clamping systems, as well as essential machine components for mold construction and machining.

The company is based in Oldham, UK, and provides solutions from CyTec, AHP Merkle, I-Mold, Servomold, Ermanno Balzi, and Feller Engineering.

ServoMold specializes in servo-electric automation solutions for injection moulds. They provide components like unscrewing devices and linear drives to enhance precision and efficiency in mould construction.

The company is based in Oldham, UK, and provides solutions from CyTec, AHP Merkle, I-Mold, Servomold, Ermanno Balzi, and Feller Engineering.